A pretty common question I see on the DJ TechTools forum is about channel faders that are acting up, jumping around and not responding like they should. The normal answer is to clean and lubricate your cross-faders – that will usually fix the problem. However, when my cross-faders started to act up, I couldn’t find any good info on what exactly needed to be done. So as I was doing my maintenance, I shot some video and did a little walkthrough to make it a little easier for people who might be having the same problem. As a bonus, while I was inside the VCI I went ahead and lubricated my jog wheels as one of them felt like it was grinding a little when I spun it.

BILL OF MATERIALS

What you’ll need to complete this little bit of maintenance is a phillips screwdriver, canned air, isopropyl alcohol, fader lubricant and jog wheel grease. The Caig line of lubricants and cleaners seems to be highly regarded throughout the DJ community so I went with their DeoxIT G5 lubricant. Whatever you decide to use make sure it’s safe for electrical connections with plastic. For lubricating the jog wheels I used a very small amount of carbon-enriched conductive silicon grease.

GETTING TO IT

- First you’ll need to remove the fader knobs and the bottom faceplate, then remove the six screws for the faders. The faders will fall through the slots as the knobs aren’t on them, but that’s fine.

- Then turn over the VCI and remove the one screw towards the bottom rear of the unit and the four screws on the sides. Slide the baseplate forward a little, lift up and set it to the side.

FADER CLEAN AND LUBE

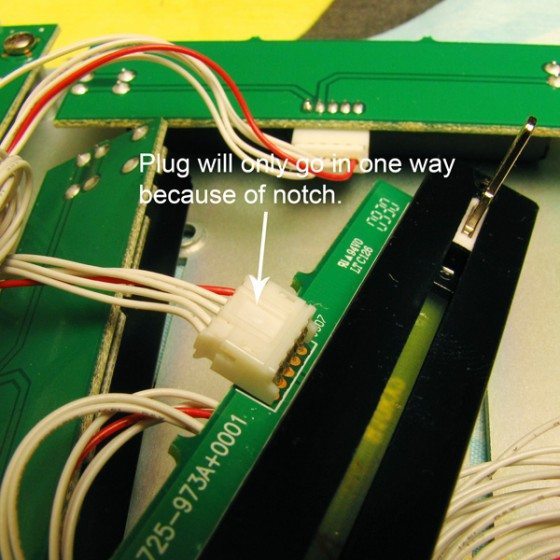

Your faders will be loose inside, so all you have to do now is unplug them one at a time (see photo for where to grab the plug), blow a few short bursts of canned air inside the fader slot to get out large pieces of dust and contaminants.

Set your fader in a small container and pour just enough alcohol in to cover the top of the fader. Move the fader back and forth while the whole piece is submerged in the alcohol to clean out any contaminants that may have built up over time.

Remove the fader from the bath and gently tap out the bulk of the alcohol that remains inside. Next you’ll take your canned air and gently blow off any remaining alcohol. Eye protection is a good idea here as alcohol that might blow into your face probably wouldn’t feel too good.

Next spray just a quick, short burst of lubricant inside the fader and slide it back and forth to distribute the lubricant evenly inside, plug it back in and repeat the procedure for the remaining faders. You can also put in a drop or two of a more heavy type of fader lubricant, although I chose not to because I have a dog and a cat and I live in an old dusty house. My thought was that with all of these things combined a heavier lubricant might attract some pet hair and dust, which would just cause me more problems later on.

JOG WHEEL LUBRICATION

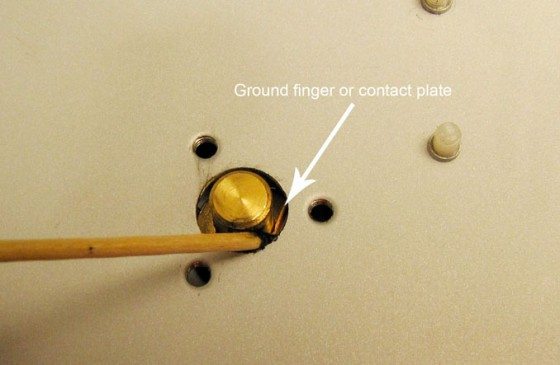

If you’re going to lubricate your jog wheels, remove the three screws holding the white plastic piece on. If you look inside you’ll see a thin plate that contacts the rotary post acting as a ground finger. You want to get your conductive lubricant between the plate and the rotary post. A very small amount of conductive lubricant should do the job fine. In case you missed it, I said conductive. If it’s not conductive you’ll lose your touch sensitivity on the jog wheels!

You don’t need to take the jog wheel apart. This photo is just to illustrate what it looks like inside and give you a better idea of where you’re trying to put your conductive grease.

It’s important to make sure the bushing is in alignment when you put it back on. Follow the steps outlined in the video to make sure it’s put on securely and centered just right.

REASSEMBLY

One final thing you can do before putting everything back together is to check the cardboard piece and make sure it’s secure. A once over of all the plugs is also a good idea while you have the VCI open.

You’ll want to screw the faders back in while the back is off so you have access to them from the other side. Make sure you don’t have any wires between the faders and the faceplate as they’ll get pinched, and that could potentially cause problems. Another thing I want to point out is that it’s possible to screw the fader screws into the slot the fader slides in, so make sure you’ve got all the holes lined up just right.

So that’s it. A good detailed walkthrough of how to do a relative simple procedure that will keep your VCI running smoothly and letting you bust out more super-awesome mixes.

Song credit in the video goes to DJ TechTools forum member, Lambox. Check out his Soundcloud page here http://soundcloud.com/lambox

After serving as the resident DJ in several different clubs in the late 80’s and early 90’s, Chris (photojojo) has recently returned to the DJ world after a long hiatus. A regular contributor to the DJ TechTools forum, he’s glad to have found the new internet home away from home where he can be found offering up help whenever he can.